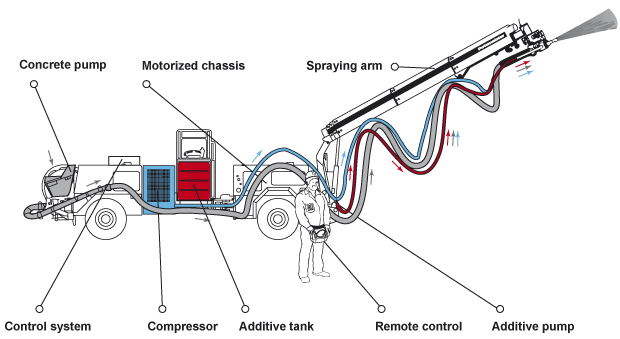

Mechanized wet-mix spraying is the most efficient method for projects with high shotcrete production. It is primarily applied for underground works in order to increase operator safety.

The concrete is introduced into the hopper of the concrete pump and transported through the concrete line to the spraying nozzle, where it is mixed with compressed air and accelerator to be sprayed on the substrate.

Concrete pump: low pulsations for a constant concrete flow

The concrete pump is in charge of conducting the concrete mixture up to the nozzle of the spraying arm. Wet-mix shotcrete is usually pumped with double piston pumps.

The pump design is aimed at minimizing the pulsations and thus the discontinuity of the concrete flow, in order to guarantee a homogeneous application of the sprayed concrete. In this way, the required quality and layer thickness is achieved, and rebound (concrete that does not stay on the wall) is reduced.

- Operation of a double piston concrete pump

Spraying arm: application with long reach

The spraying arm of the mechanized equipment positions the concrete flow at the required spot. Reaching spraying distances up to 17 m, there is no need for scaffolding or telescopic elevation platforms.

Concrete, accelerators and air are mixed in the spraying head to be applied through the nozzle. The nozzle design and dimensions are crucial for the correct compression of the concrete and minimizing rebound.

Air compressor: spraying and compaction of the concrete mixture

The air compressor is in charge of providing the concrete mixture with the necessary kinetic energy for being sprayed and compacting. For this purpose, the shotcrete has to impact on the surface with a certain velocity, which is not only achieved by the air flow provided by the compressor, but only in combination with the right nozzle diameter. For example, an air flow of 12 m3/min with a nozzle diameter of 65 mm does not provide sufficient kinetic energy. However, the same flow with a nozzle of 35-40 mm does, provided the right spraying distance (1-2m) is maintained.

Additive pump: dosification of accelerator

In order to obtain the required early strength development, it is necessary to speed up the hardening of the concrete, which requires the use of accelerators. To ensure that the dosage is in accordance with the concrete flow at any time, the dosing device is synchronized with the concrete pump.

Control system: the equipment’s brain

- Monitors the correct relation of accelerator dosage and concrete being pumped

- Manages the correct functioning and security of the concrete pump

- Collects the spraying data for download and processing

Remote control: secure management of the equipment

By the use of the remote control, the operator can manage and modify the principal components of the sprayed concrete (concrete and additive) as well as the equipment’s components (spraying arm and nozzle). There are wireless or cable remote controls, allowing the operator to work always from a secure area.

Motorized chassis: reach the excavation face across any terrain

The equipment components are mounted on a motorized chassis to drive it to the spraying area. In limited spaces, characteristics such as dimensions, direction and turning radius are important. Its motorization, angles of attack and climbing ability are critical for reaching areas with slopes and irregular terrain.

Visit Putzmeisterunderground.com to see our complete range of mechanized shotcrete equipment.