Shotcrete in underground works can be applied with different methods and equipment: wet-mix spraying or dry-mix spraying, manual or mechanized equipment.

The wet-mix already includes all ingredients before pumping, including water, whereas it is added to the dry-mix in the nozzle just before spraying.

Mechanized wet-mix spraying offers substantial advantages, although manual dry-mix shotcreting is often used in environments with extreme temperatures, in small tunnels and galleries or for logistic reasons.

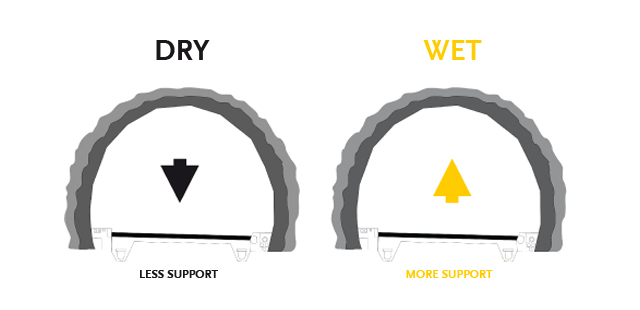

1. Higher quality and homogeneous support

The water / cement relation is controlled automatically when using mechanized wet-mix spraying, whereas it depends on the operator when manual dry-mix spraying is applied. The water / cement relation is directly related to the strength of the shotcrete support.

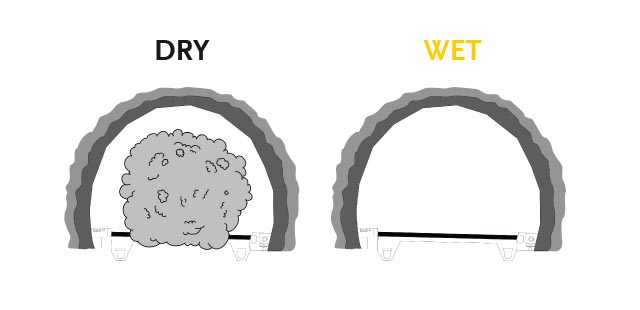

2. Healthier and safer working conditions

Dry-mix spraying generates a lot of dust, which compromises operators´ health in the long run. Besides, manual spraying is an exhausting job, so the operator cannot fully concentrate on spraying finish quality. In general, mechanized spraying increases operator safety.

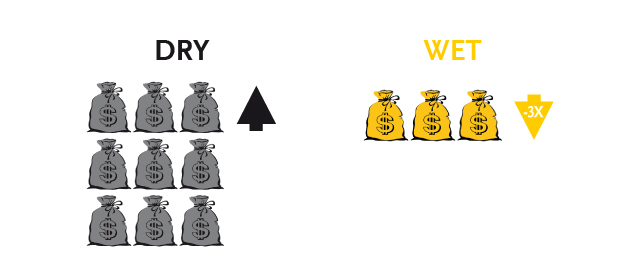

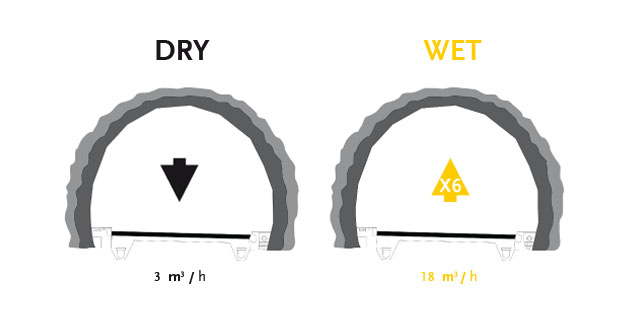

3. Energy savings

One mechanized concrete spraying equipment achieves the same performance as three machines for manual dry-mix spraying, working all with the same power and air requirements. Therefore, mechanized wet-mix spraying of saves energy and money.

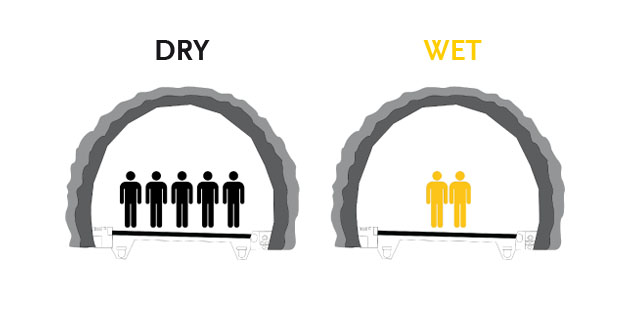

4. Less manpower required

A mechanized shotcrete equipment can be operated by two nozzlemen, while manual spraying requires more manpower.

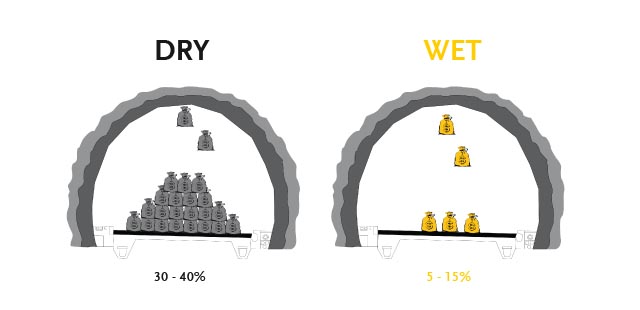

5. Less rebound

The amount of water in the shotcrete mix, among other factors, influences rebound quantity. The wet-mix method provides more control over the shotcrete mix, reducing rebound in comparison to the dry-mix method.

6. Higher spraying output

Mechanized concrete spraying equipment offers higher spraying outputs than manual spraying, the max. concrete flow being between 20 and 30 m3/h.

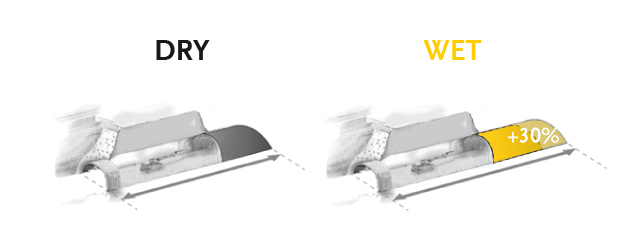

7. Time savings

Higher spraying outputs and fasterpreparation of the shotcrete mix allow total time savings of up to 30% with mechanized wet-mix spraying.

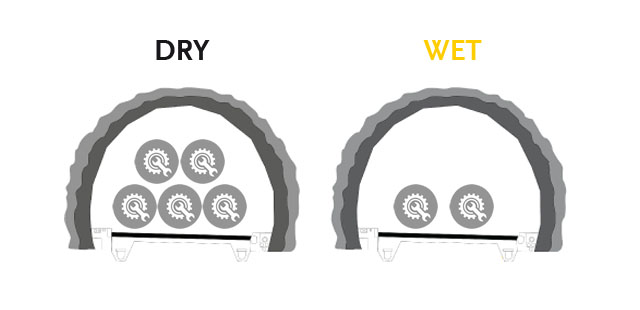

8. Less wear and tear

Dry-mix spraying is more abrasive and causes higher wear ant tear so that more spare parts are required.

Obtain high-quality shotcrete with mechanized concrete spraying equipment!