Tunnels are a many-splendoured thing. For motorists, they often impress with their seemingly endless length and the remote locations they so seamlessly connect. Water and mountains are no obstacles to them – they truly are a work of art. But have you ever considered the process behind their construction?

In today’s blog post, we explore the wonderful of formworks, and their role in the tunnel-construction process. Join us as we discover the various types of systems available, and what makes them special in their own right.

What is formwork?

Formwork is the name given to the mould into which fresh concrete is poured. It is used to shape the concrete as well as support it until it has cured. Although traditional formwork systems for tunnel construction were low-tech, labour-intensive productions, today’s systems have come a long way – thanks in part to the expertise of innovative companies like Kern Tunneltechnik.

Let’s have a look at the various types of formworks available today depending on the tunnel being built.

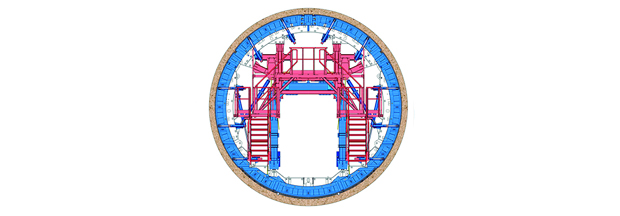

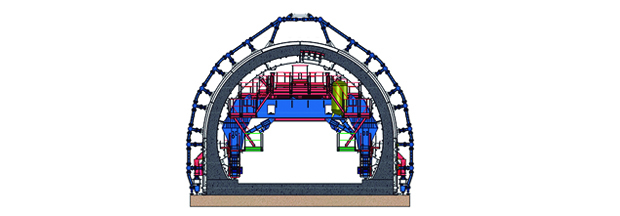

Polycentric Formwork

When’s it used? The polycentric variety is used for your average tunnel. Its customizable nature means your project requirements call the shots.

What makes it special? This formwork is hydraulically operated by remote control, and can be aligned with the tunnel section without manual work. What’s more, the setup and striking phases are regulated by an automatic locking system. In terms of final quality, the formwork is coated with a nanotech ceramic layer to protect against abrasion and corrosion, which also helps to minimize cleaning times and reduces the need for protective oils.

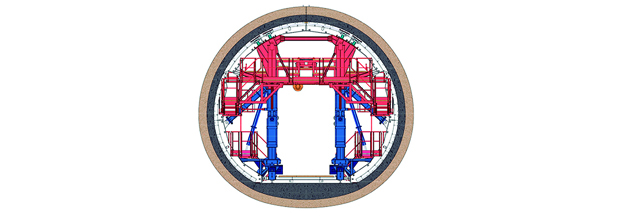

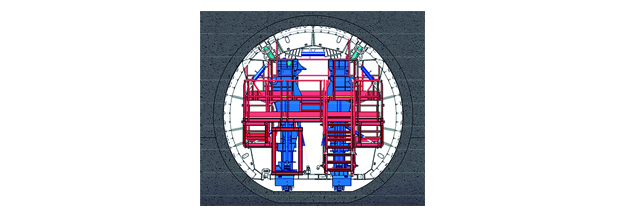

Fullround Formwork

When’s it used? The fullround formwork, as the name suggests, is used for the construction of a 360° tunnel.

What makes it special? The system is designed to carry out a 360° secondary concrete lining, guaranteeing a final finish without holes or steps. Also, the steer form section is full hydrostatic and can achieve a rate of advancement of 300 metres per week.

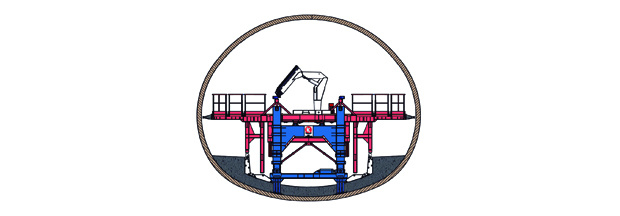

Invert Formwork

When’s it used? The invert formwork is used in the construction of the tunnel invert prior to the vault section.

What makes it special? The tunnel invert can be customized as per the customer’s requirements whereas the transport is performed by a double-length telescopic traveler. What’s more, high up-lift concrete pressure is controlled by a bespoke structure that reacts on the primary lining.

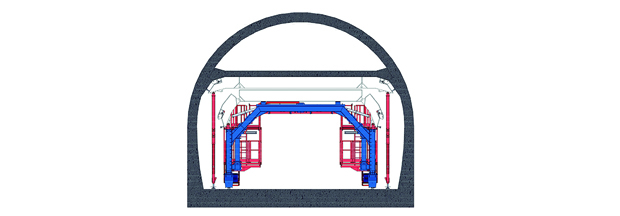

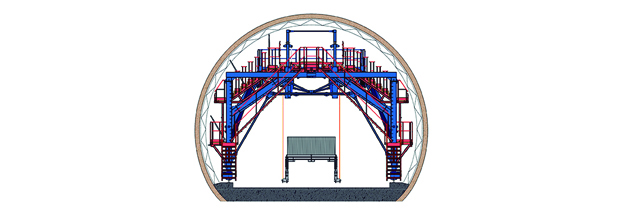

Slab Formwork

When’s it used? The slab formwork is utilized in the construction of a secondary lining deck.

What makes it special? The slab formwork is engineered to resist pressure given by a concrete thickness of more than 2 meters. Not only that, the machine in question comes equipped with a service gantry with a concrete distribution system, which speeds up the work for operators and allows for a safer working environment. The transport traveller is designed to work with more than five slab formworks, making it possible to perform a continuous secondary lining, relocating sections of slab formwork while other sections are in the casting phase.

External Formwork

When’s it used? This variety of formwork is used in the construction of an inlet external tunnel.

What makes it special? The external formwork works together with the main internal formwork to create a “false tunnel” at the entrance of the main one. Designed with modular elements that allow one to reuse the machine in other projects with different geometries, the machine can be self-propelled and comes equipped with drive units to cast the secondary lining of long tunnels.

Bypass Formwork

When’s it used? This formwork is used in the construction of the secondary lining of crosspassage tunnels between two main lines.

What makes it special? The machine can be can be reused in different geometries within the same project. The formwork is calculated to work with concrete hydrostatic pressures.

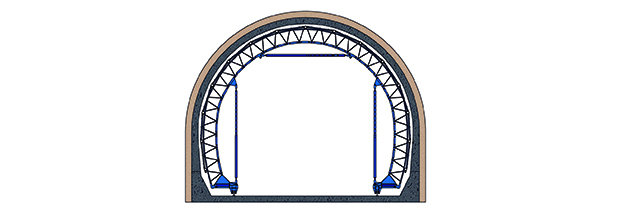

Reinforcement Gantry

When’s it used? This variety of formwork is used for the installation of the reinforcement provisions inside the tunnel in H&S conditions.

What makes it special? The machine comes with telescopic hydraulic devices to install the reinforcement, reducing the need for manual handling and speeding up the process. The gantry can achieve a crown reinforcement lifting capacity of up to 15 tons.

Curing Gantry

When’s it used? The curing gantry is a secondary lining post-treatment device able to control the temperature and humidity in air chambers in accordance with customers’ specifications.

What makes it special? Setup and monitoring are electronically controlled through the use of an advanced PLC system. What’s more, the data are recorded and stored every hour over a period of one month. Finally, the curing gantry is composed of modular elements adaptable to various geometries.