For the application of sprayed concrete in underground works, different methods and equipment can be used: wet-mix spraying or dry-mix spraying, manual or mechanized equipment. When evaluating which option is the most profitable, it is not sufficient to only compare the initial cost.

This post will help you calculate the total operating cost of your project to find out which spraying equipment is the most cost-efficient. We will take the construction of a railway tunnel in Spain as an example for comparing the cost associated with different shotcreting methods.

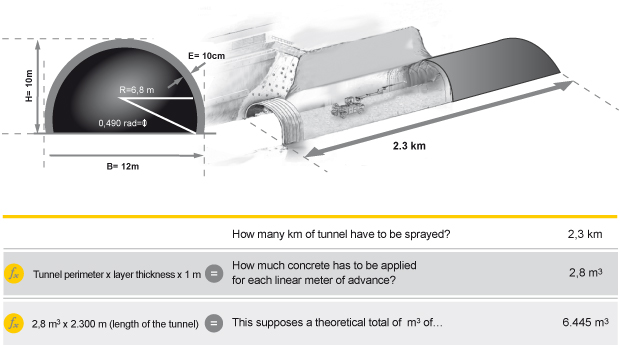

Estimate how many cubic meters of concrete you need to spray

The best way of analyzing the operating cost of shotcreting is by cubic meter of concrete to be applied:

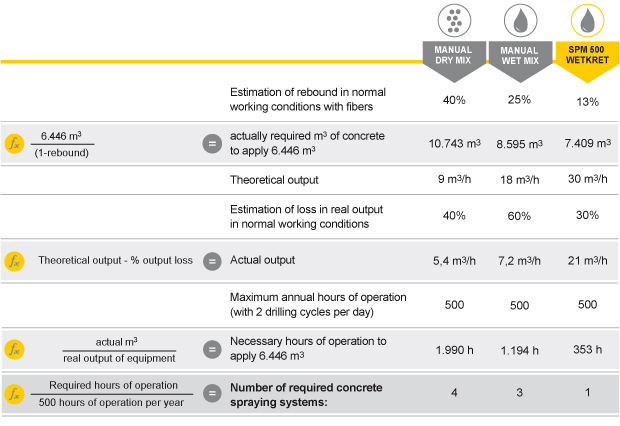

Calculate how many shotcrete machines it takes

Taking into account the concrete output and rebound level of the different spraying machines, you can calculate how many machines it takes to spray the required concrete.

In our example, the construction company analyses the cost of spraying 6.446 m3 of fiber-reinforced concrete in 12 months. Manual wet- and dry spraying is compared to using a Putzmeister SPM 500 WETKRET for mechanized wet-mix spraying.

Conclusion: Only one mechanized concrete spraying system is enough to complete this project faster than several manual spraying machines, due to the saving of actual concrete to be applied and a higher output.

Calculate the total shotcrete operating cost

To calculate the total operating cost, take into account the following:

- Equipment start-up cost

- Operator training cost

- Labor cost

- Spare parts cost according to hours of operation

- Working hours for clean-up of rebound

- Power consumption

- Fuel and lubricants cost

- Optional costs:

- Scaffolding

- Telescopic elevation platforms

- Air compressors

- Concrete transport

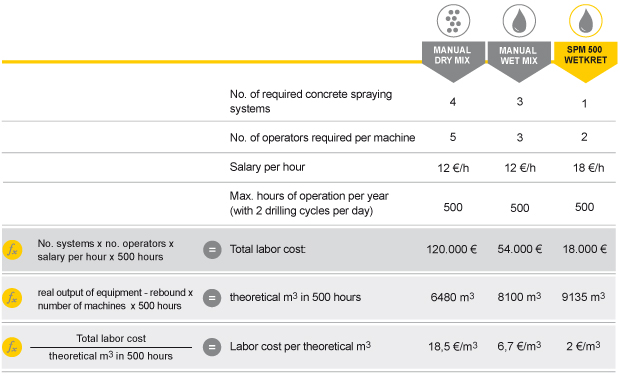

Let´s have a look at some examples:

Labor cost: One mechanized spraying system does the equivalent work of various machines for manual spraying and can be managed by fewer operators, as it requires less physical strength. Therefore the savings in labor costs are evident:

Spare parts: As manual spraying requires more machines, the consumption of spare parts will also be higher. The dry-mix method is more abrasive, so the wear parts suffer more.

In our example, the spare parts savings with mechanized spraying equipment amount to 54 % in comparison to manual dry-mix spraying, and 44 % in comparison to manual wet-mix spraying.

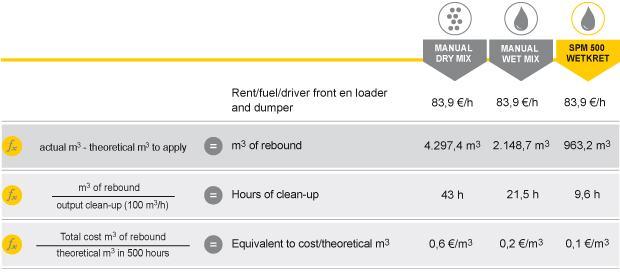

Clean-up of rebound: The higher the rebound, the longer it takes to clean it up:

Total operating cost: The sum of all items in our present case (equipment start-up, operator training, labor, spare parts, rebound clean-up, power consumption, air compressors) is the following:

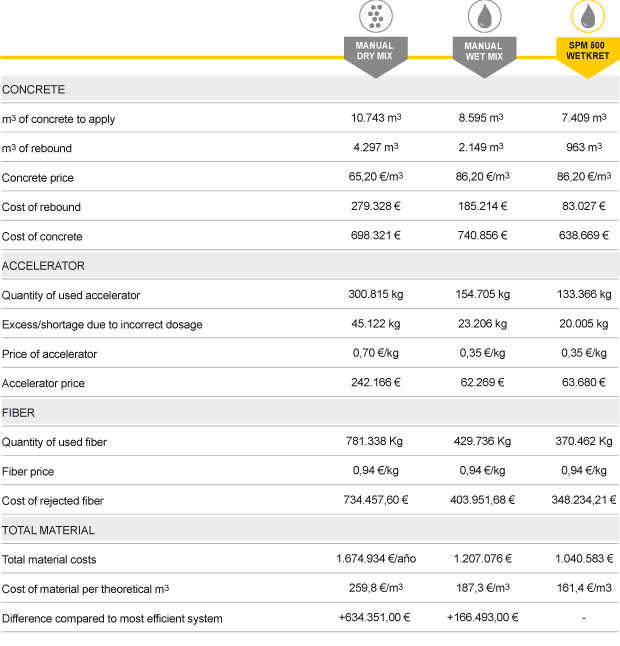

Calculate the material cost

The comparison of the material costs in our example led to the following results:

When is it profitable to invest in mechanized concrete spraying equipment?

The graph illustrates the cost per cubic meter applied to the substrate, taking into account the cost of ownership, operating costs and material costs associated with the different spraying methods.

Although the acquisition of a mechanized shotcrete machine supposes a higher initial cost, it can be observed that from a certain volume of shotcrete on it is the most cost-efficient method due to the lower cost per cubic meter. In our example, from a volume of 2.1190,29 m3 onwards, mechanized concrete-spraying is more cost-efficient than manual dry spraying, and from 6.451,61 m3 it is more cost-efficient than manual wet spraying.

Would you like to know what is the best option for your project? Contact us!